What Factors Determine Which Material Is Best for Vessel Construction

Aluminum is also among the perfect materials for use in the manufacture of pressure vessels. Knowledge of the owner or operator reliability integrity and Safety Management.

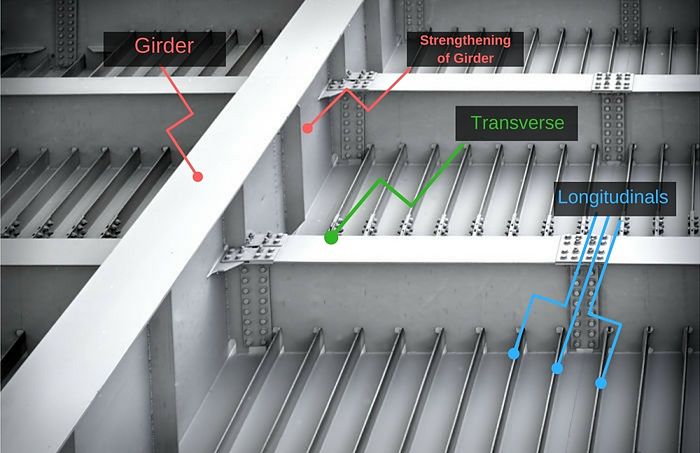

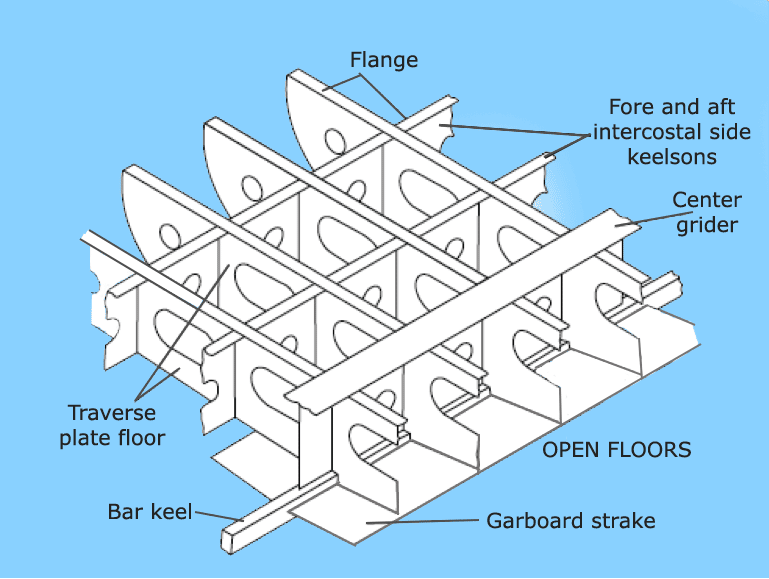

10 Basic Ship Construction Terms For Seafarers To Know Myseatime

This is particularly applicable in mechanical.

. The below factors should be considered when planning the scope of a vessel inspection. If the code of construction does not include a. Materials allowed for constructions are listed in Section II Part D and also in the code of construction eg.

Mechanical Forces or Loads Wear and tear. The necesaary factors that shall be considered for designing pressure vessel as per ASME Sec VIII requires following minimum considerations. Carbon steel is an alloy between carbon and iron.

Other factors such as operating temperatures and physical environment can also be at play in tank. Section VIII Division 1. Material size operating pressure process conditions.

Where K Ic is the plane strain fracture toughness of the pressure vessel material. Carbon Steel Fairly economical and has wide temp range. Aluminum is more preferred although its high price and maintenance cost are a discouraging factor.

All Parr raw materials are carefully identified throughout the manufacturing process for trace ability as required by ASME and other codes. For example the chemicals in the tank can be corrosive damaging the tank materials. Center for Energy Studies Louisiana State University.

Also known as mild steel. Therefore it is very important to make the right choice in selecting the appropriate material. This post describes the essential design factors common.

Factors Effecting in the selection of Materials For Engineering purpose. The materials used for vessels go a long way in determining its reliability and safe operation. Carbon steel and stainless steels are some of the most common metals used in construction.

The key factors are included in the selection of construction materials for pressure vessels to avoid damage during the service. In equation 3 inserting the limiting value of as the yield strength f of the pressure vessel material and. Although the material is well capable of using for the design it may be difficult to manufacture.

The proper selection of materials to be used in a particular construction project depends on the following factors. Its strongest characteristics are what make it ideal and below are a few of. Obviously there are many other factors that you should consider including corrosion of the vessel material eg.

A wide range of construction materials is available. Market conditions design type and class construction. For a cheaper material selection Use concentrations that self passivate the surface Use other temp press compositions Consider how you might minimize an expensive choice in.

Product weight and viscosity. Heavy and thick products flow through your vessel. An iron container holding sea water the fatigue life of.

Several factors about your product processes business objectives and physical facility must be considered to determine the best vessel solution for your operation. The minimum temperature till which carbon steel vessel can work satisfactorily is -20F before it loses its ability to resist sudden shock. In recent times the major shift in boat material has been from wood to.

Many factors influence rig construction cost. A material consisting of two or more metals or a metal and a nonmetal What factors determine how thick a vessels walls should be.

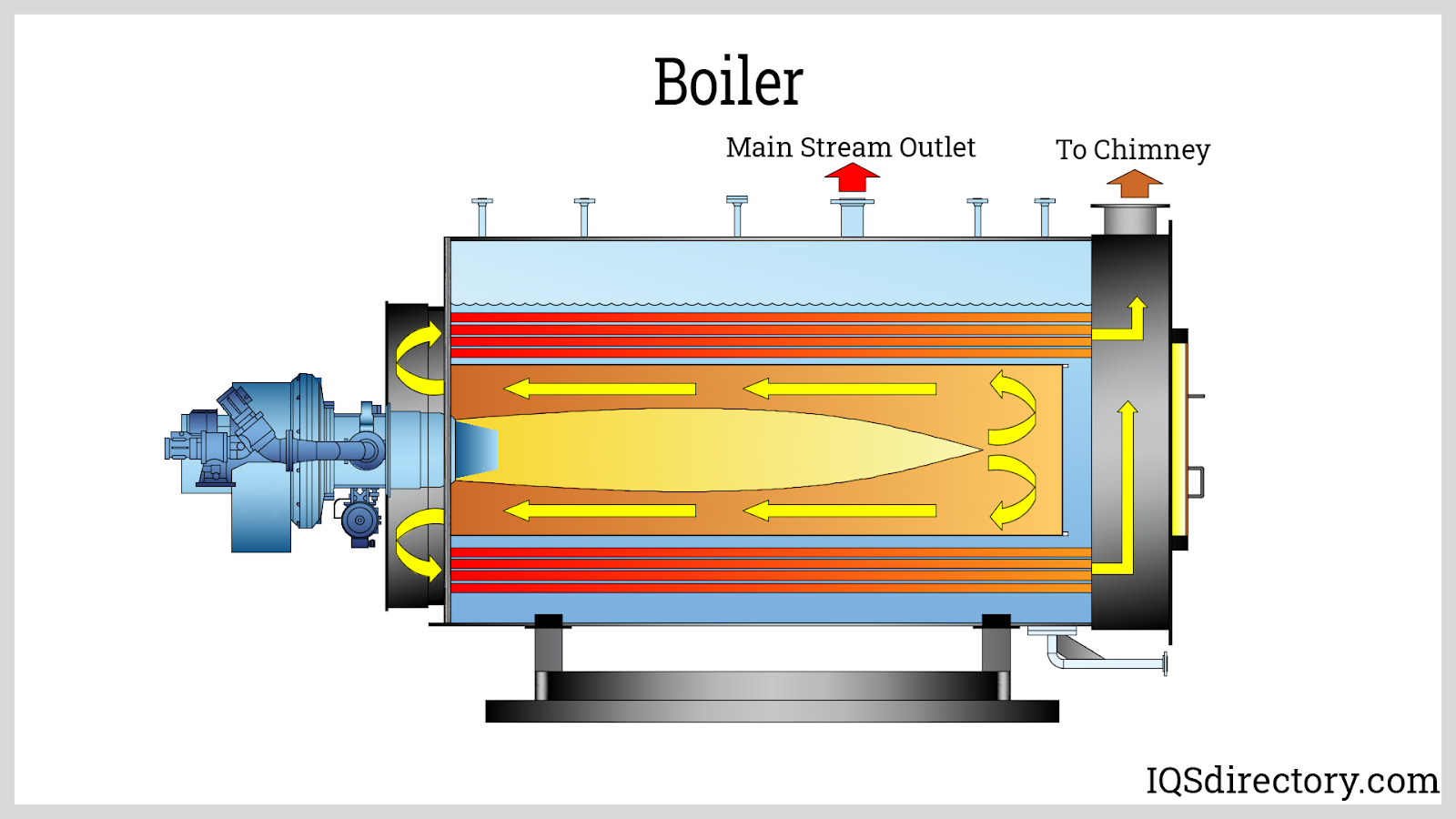

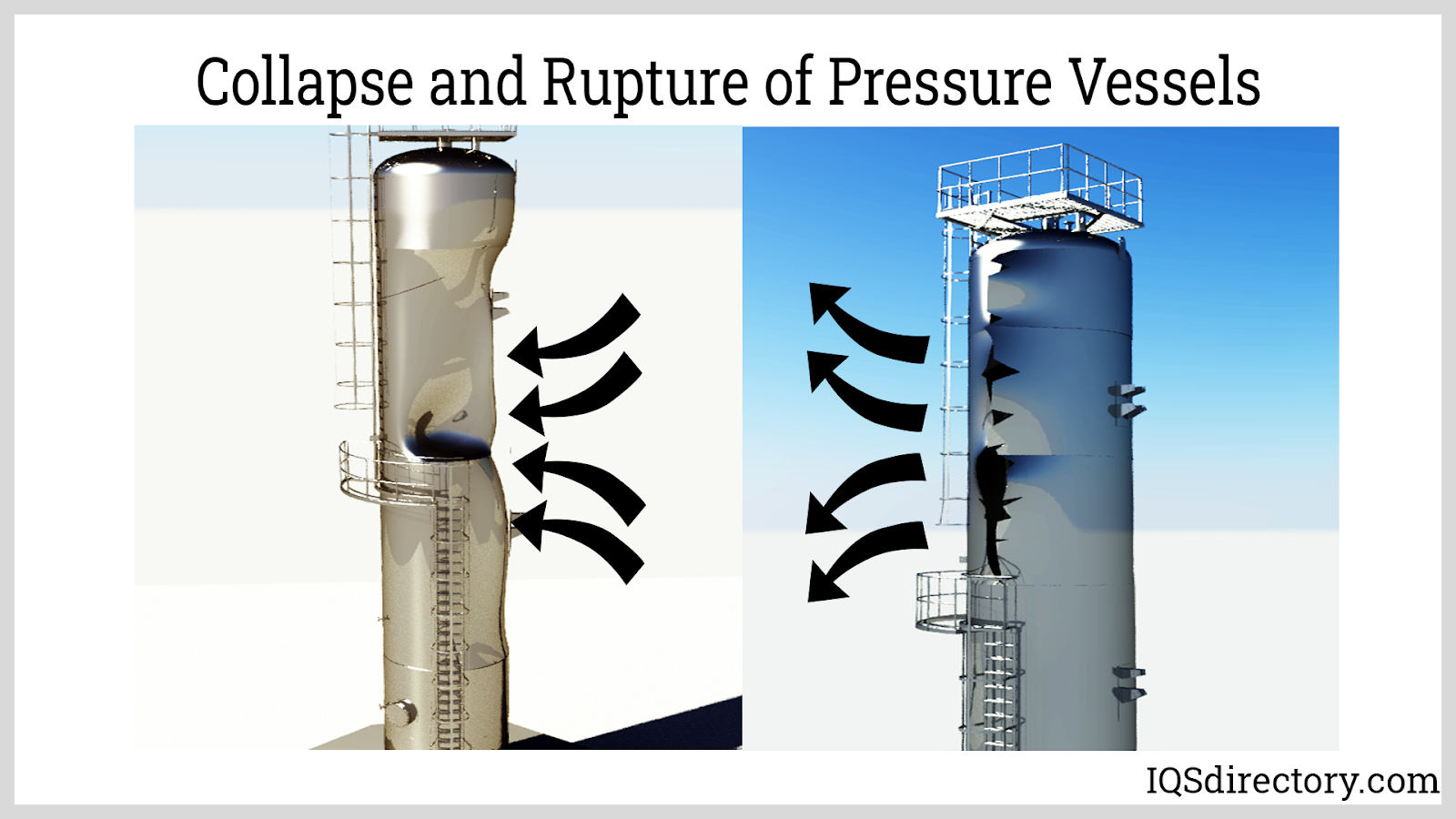

Pressure Vessel What Is It How Does It Work Types Uses

10 Basic Ship Construction Terms For Seafarers To Know Myseatime

No comments for "What Factors Determine Which Material Is Best for Vessel Construction"

Post a Comment